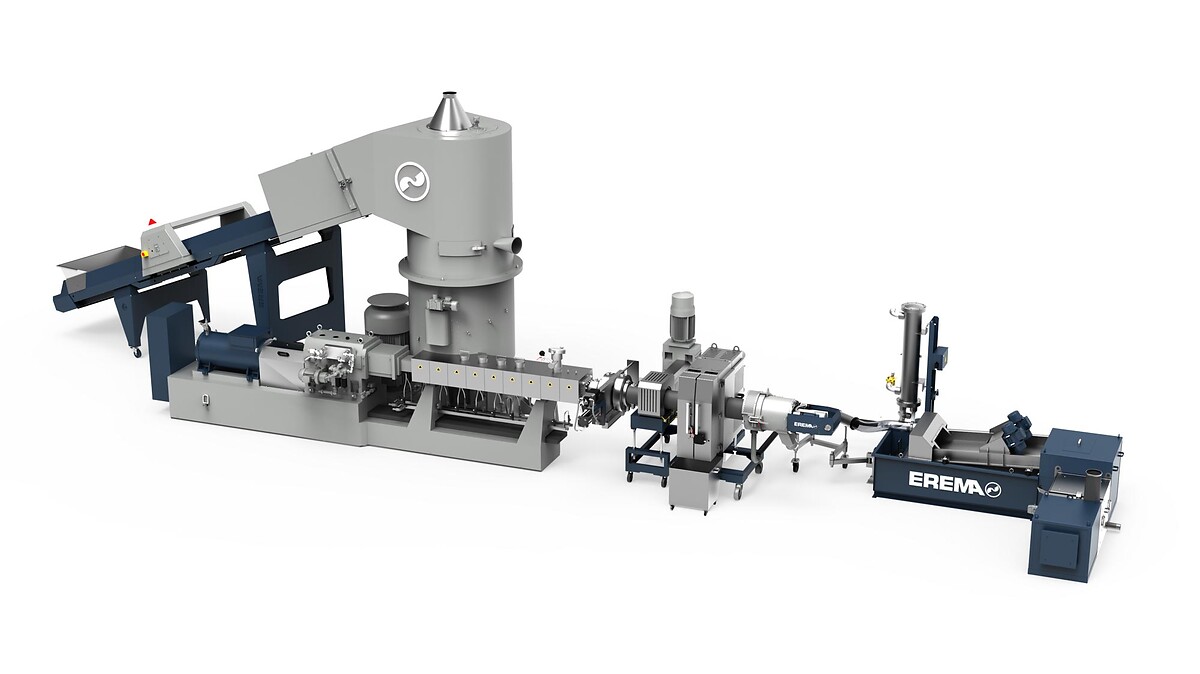

At K 2025, EREMA expands its portfolio to include high-performance twin-screw extruder technology. With the new TwinPro, the Austrian provider of plastics recycling solutions combines the advantages of a twin-screw extruder with the proven strengths of its Pre-conditioning Unit (PCU) to be used for specific recycling applications.

EREMA spent two years intensively researching, testing, and further developing the twin-screw extruder concept presented at K 2022. Working together closely with customers, they have developed a series production solution that is particularly adept at recycling production waste consisting of demanding multi-layer films. The technology also opens up new perspectives for thin-walled post-consumer regrind material.

"The TwinPro sees us bring a new product to market, and couple our unique PCU featuring Counter Current® technology directly to a twin-screw extruder for the first time," says Markus Huber-Lindinger, Managing Director at EREMA. "As a result, this system sets new standards for specific recycling tasks. During development, we focused especially on combining our strengths in material processing with the advantages of a twin-screw extruder."

Efficient homogenisation of low bulk density film for maximum recycled pellet quality in a single work step

Producing high-quality recycled pellets using complex input materials such as multilayer film consisting of PE-PA or PE-EVOH is a major challenge for the recycling process. This is where the new TwinPro comes in, with its key feature of highly efficient homogenisation.

The first stage of homogenisation takes place in the preconditioning unit (PCU), which shreds, heats, dries, compacts and buffers the input material. Optimised material preparation right at the start of the recycling process lays the foundation for consistently high-quality end products. Thanks to patented Counter Current® technology, the extruder, which is directly coupled at a tangent to the PCU, is continuously filled with heated and pre-compacted material. Even with low bulk density material like film waste, the PCU is able to deliver full throughput. The PCU covers an exceptionally wide bandwidth of input materials, with bulk densities of 30 to 800 grams per litre reliably processed in a single work step, without the need for separate agglomeration, weighing or a stuffing unit.

This is followed by intensive homogenisation in the twin-screw extruder, which is essential for multilayer films so that the different polymer types are mixed in the best possible way. This produces recycled pellets with the improved mechanical properties needed for reuse in multi-layer films. "Our TwinPro demonstrates once again that EREMA is not only a leader in single-screw extruders, but that we also offer high-performance twin-screw solutions that clearly stand out on the market thanks to our proven preconditioning unit," says Markus Huber-Lindinger.

Our TwinPro demonstrates once again that EREMA is not only a leader in single-screw extruders, but that we also offer high-performance twin-screw solutions that clearly stand out on the market thanks to our proven preconditioning unit.

Markus Huber-Lindinger, Managing Director at EREMA

Reliable feeding of very thin-walled post consumer regrind material

Originally developed for complex film waste, the TwinPro now opens up new capabilities for using twin-screw extruders in the recycling of 3D packaging. The trend towards thinner wall thickness for plastic packaging increases the demands on extrusion technology. One particular application is PP flakes that have been sorted and hot-washed from very thin-walled packaging such as yoghurt tubs. This is also a challenging application due to very low bulk density and possible moisture fluctuations of the input material. However, the TwinPro can easily process this type of thin-walled packaging that often causes problems in the material feed on conventional twin-screw systems because of its low weight and high volume. What is more, the PCU reliably removes residual moisture from the washing process and also deodorises the material.

Find out more and visit EREMA at K 2025: Hall 9, Stand: C09

and at the Edvanced Recycling Centre: Outdoor area, CE03