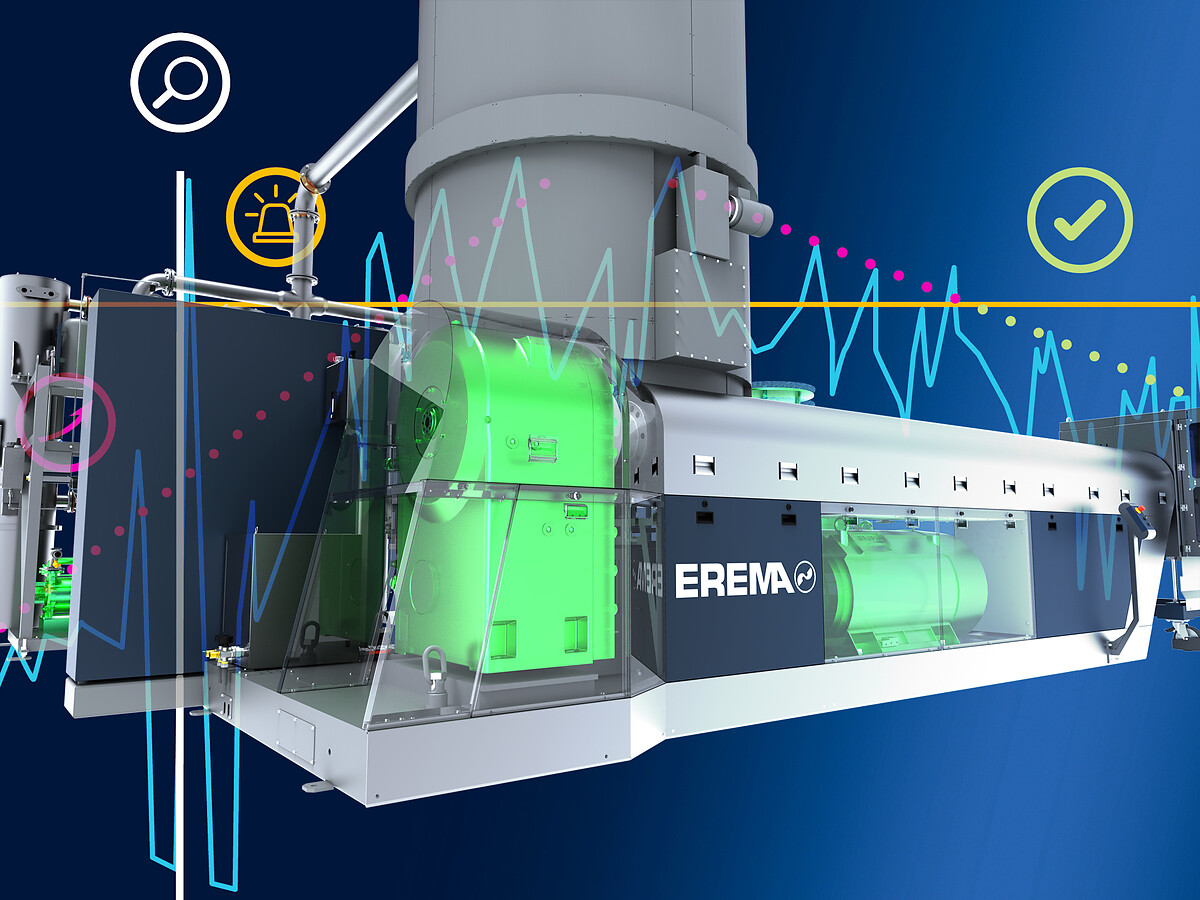

K 2025 sees EREMA expand its digital and preventive maintenance solution PredictOn:Drive with more detailed data analysis. This advanced system provides real-time insights into the operational status of recycling machinery, enabling timely maintenance interventions. This will reduce the risk of unscheduled downtime, increase machine availability and boost the productivity of the recycling system. Visualisation of the process is fully integrated into the machine display (HMI) and the BluPort® digital customer platform.

Detecting wear on key components at an early stage minimises the risk of unscheduled downtime in plastics recycling. EREMA’s PredictOn solutions enable predictive maintenance based on current process data in real time. The result is that maintenance measures can be scheduled in good time and, in contrast to routine preventive maintenance, are only performed if they are really necessary. Personnel deployment and spare parts procurement can be better coordinated, reducing maintenance costs and increasing system uptime. PredictOn provides instructions on recommended maintenance tasks, supported in part by video tutorials.

Enhanced PredictOn:Drive

PredictOn:Drive monitors all the main drive trains on the preconditioning unit and the extruder, as well as the vacuum pump status on PET systems. The new in-depth data analysis option makes PredictOn:Drive even more powerful because it detects any abnormal process values and automatically triggers remote analysis using AI-supported algorithms to identify potential damage and pinpoint the affected components. In the event of anomalies, the machine operator receives precise diagnoses and specific recommendations for action directly on the BluPort® platform. Monthly status reports also provide an analysis of all monitored components.

BluPort® digital services platform puts all the data in one place

The visualisation of this predictive maintenance tool is fully integrated into the BluPort® online platform. It accompanies customers through the entire product life cycle, from initial contact to maintenance and upgrades, and potentially to a subsequent repurchase of the equipment. All information on quality control, spare parts, contact persons and system data is displayed in one place, accessible at any time, barrier-free, and synchronised between desktop and mobile devices. Over 4,500 users worldwide benefit from the advantages offered by this platform. "BluPort® lets us offer a comprehensive digital ecosystem that supports customers in their daily work, puts them in touch with the right contacts, and keeps everyone involved on the same level of information," says Christoph Krump, Head of Business Unit Service at EREMA. "Together with our experts' know-how, we offer our customers a strong network of digital tools and technical expertise wherever they are."

"Together with our experts' know-how, we offer our customers a strong network of digital tools and technical expertise wherever they are."

Christoph Krump, Head of Business Unit Service at EREMA

Experience digitalisation live at K

Visitors to K can experience PredictOn live in action on an INTAREMA® TVEplus® DuaFil® Compact, processing different input materials. The machine is equipped with PredictOn:Drive and PredictOn:Plastification Unit. The BluPort® displays at the EREMA stand and at the Edvanced Recycling Centre in the outdoor area will let visitors see how the assistance systems work.

Find out more and visit EREMA at K 2025: Hall 9, Stand: C09

and at the Edvanced Recycling Centre: Outdoor area, CE03