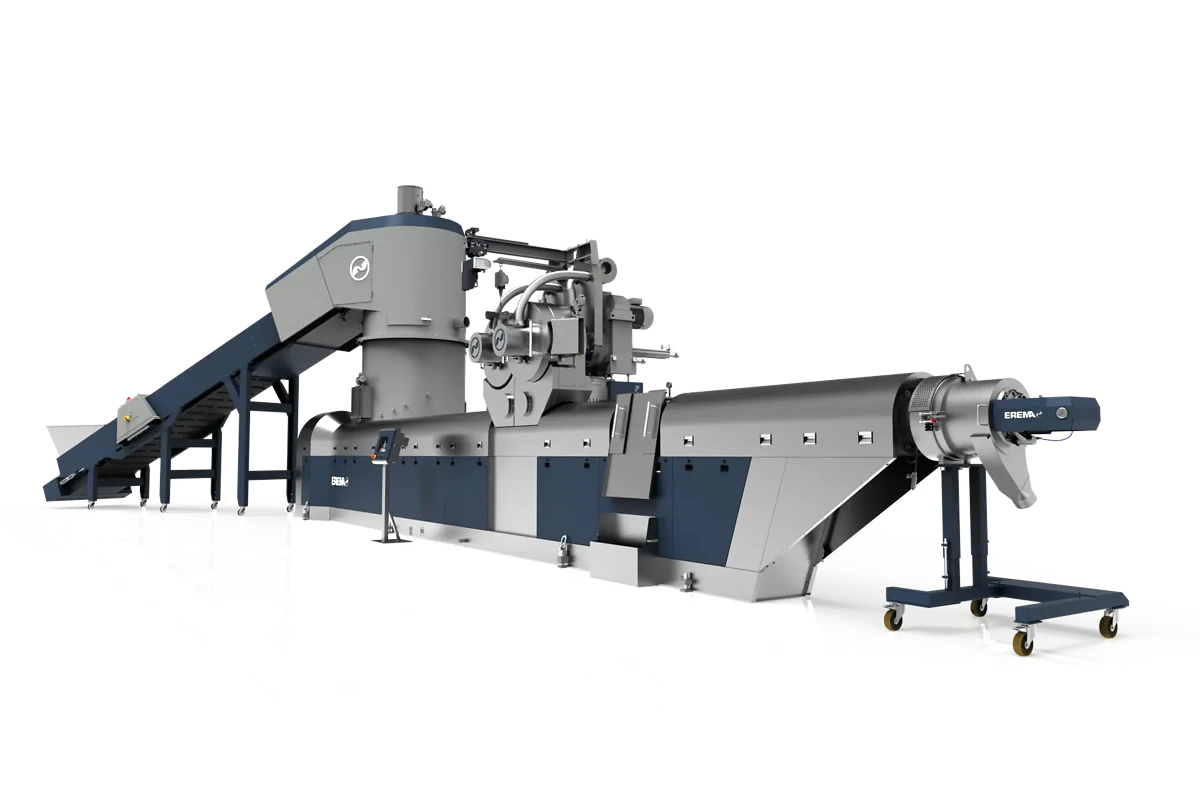

A compact footprint and high throughput are increasingly decisive key parameters in post consumer recycling. EREMA is responding to this by upscaling the INTAREMA® series and launching the 2021 model without a cascade at the K 2025.

“It is thanks to our latest innovation in filtration that we have been able to implement the system on this scale. We will be demonstrating this innovation live at K 2025.”

Markus Huber-Lindinger, Managing Director at EREMA

Based on TVEplus® and EREMA PCU technology, the new 2021 produces even higher quality recycled pellets. Counter Current® technology makes a significant contribution to this because it continuously feeds the extruder with preheated material that is 5 to 15 degrees Celsius warmer than with conventional cutter compactor systems. This is a technological advantage, especially for an extruder screw with a large diameter with correspondingly deep screw flights. The melt is processed more gently with less shearing and without additional particle size reduction. This makes it easier for impurities to be extracted by the melt filter, which is a key element of the new development. "It is thanks to our latest innovation in filtration that we have been able to implement the system on this scale. We will be demonstrating this innovation live at K 2025," says Markus Huber-Lindinger. The system is also available with DuaFil® Compact technology for even more efficient filtration.

Find out more and visit EREMA at K 2025: Hall 9, Stand: C09

and at the Edvanced Recycling Centre: Outdoor area, CE03