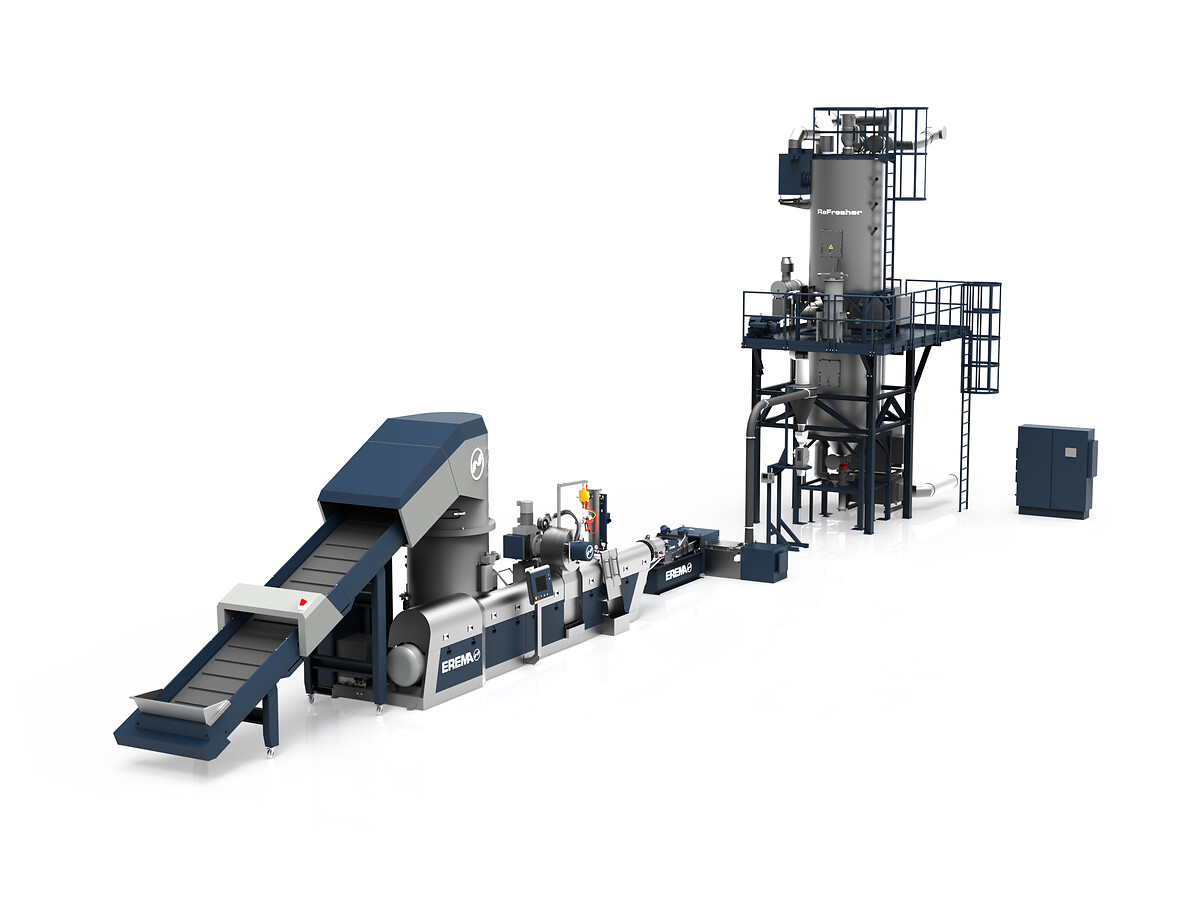

Odour is one of the biggest challenges in recycling post-consumer polyolefins, especially when aiming for high-quality applications. Since 2016, EREMA has been addressing this with its ReFresher technology. When combined with the INTAREMA® TVEplus® extrusion system, it produces odour-optimized and food-safe recycled pellets.

The ReFresher and INTAREMA® TVEplus® form a highly efficient duo for odour removal. The extruder tackles highly volatile odour substances during the extrusion process, while the downstream ReFresher module removes low-volatile, high-molecular odour compounds.

Today, ReFresher installations worldwide process over one million tons of polyolefins per year, serving film and regrind applications alike.

The ReFresher removes even low-volatile, high-molecular odours from post-consumer recyclates. This ensures recycled pellets can meet the highest quality standards, including sensitive applications in food-safe packaging and premium consumer goods.

Clemens Kitzberger, Business Development Manager

Energy-efficient and food-grade-approved

The ReFresher keeps the pellets at the temperature required for fast and deep-cleansing discharge of volatile materials and thereby only uses minimal energy input. This is possible, because the pellets are already preheated through the extrusion process. Thanks to the stable, well-prepared input provided by the INTAREMA® TVEplus®, only short residence times are required inside the ReFresher.

The anti-odour system opens up new opportunities for high-quality applications, like food-safe packaging, automotive components, home and lifestyle products, and also sensitive personal care items. The process has been classified by an American food safety authority as suitable for feeding recycled PO pellets back into the production of food packaging. In the EU, the permit for food-safe recycled pellets is based on a "novel technology" (Regulation 2022/1616). EREMA supports recycling companies in generating data and evidence for the EFSA (European Food Safety Authority) assessment process.

Try before you invest

EREMA offers compact ReFresher units for onsite trials at your production facility, allowing recyclers to customize solutions to their specific requirements. This hands-on approach ensures that investments align with the end-use quality expectations.

Discover more: https://www.erema.com/en/refresher/