While growth rates in the production of fibres and textiles are high, the circular economy has hardly become established in this segment. With the innovative PET fibre-to-fibre recycling plant INTAREMA® FibrePro:IV and its new fibres and textiles business unit EREMA is intensifying development of recycling solutions for this application. Thanks to its especially gentle material preparation and efficient removal of spinning oils, the rPET produced with the new plant can be reused in proportions of up to 100 percent for the production of very fine fibres.

PET is regarded as a key material for the production of synthetic fibres. Around two thirds of the total volume of PET goes into the production of PET fibres for the textile industry. This highlights the importance of high-quality recycling solutions for the circular economy.

"The fibres and textiles application is not completely new to us, because our PET recycling machines have already been used in fibre recycling. However, in order to reuse these recycled fibres in higher-quality applications, a new technological solution was needed," explains Wolfgang Hermann, who is responsible for the development work for this application as Business Development Manager at EREMA Group GmbH.

EREMA drives the topic PET fiber-to-fiber recycling with strong solutions. This is important for the circular economy of today. And: an important milestone for the textile recycling of tomorrow.

Wolfgang Hermann,

Business Development Manager Application Fibres & Textiles EREMA Group

New IV Uptimiser

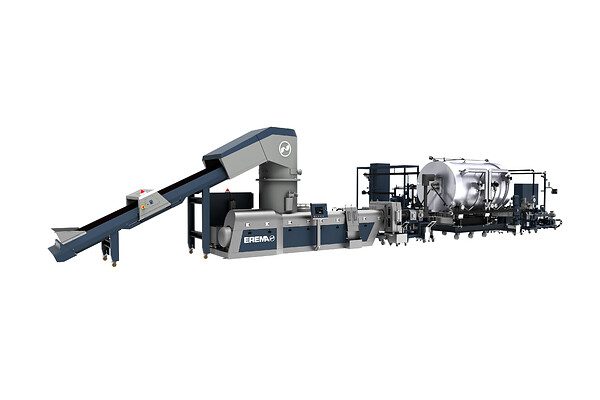

By combining proven INTAREMA® technology with a new IV Uptimiser, EREMA succeeds in processing shredded PET fibre materials heavily contaminated by spinning oils in such a way that the finest fibres can be produced again from the recycled pellets. The system, which joins EREMA's machine portfolio as the INTAREMA® FibrePro:IV, is characterised by a longer residence time of the PET melt. This is an essential factor for achieving high quality recycled pellets, as it allows the spinning oils and other additives used to improve the handling of the fibres during manufacturing to be removed more efficiently than in conventional PET recycling processes. Following extrusion, by polycondensation the intrinsic viscosity (IV) of the PET melt is increased in the new IV Uptimiser and under high vacuum to the precise level that is needed for fibre production.

"Including filtration the output quality that we achieve with this recycling process is so high that ultra-fine fibres of up to 2 dtex can be produced using these rPET pellets, with an rPET content of 100 percent," says Markus Huber-Lindinger, Managing Director at EREMA. Waste PET fibre from production processes can therefore be further processed into rPET filament fibre, carpet yarn and staple fibre.

A strong fibre package – INTAREMA® & IV-Uptimiser: While the INTAREMA® prepares the material for extrusion using its Preconditioning Unit and Counter Current technology to ensure perfect homogenisation, pre-drying, removal of volatile components, and subsequent gentle PET melting, the new IV Uptimiser ensures repolymerisation, IV lift and efficiently cleans the fibres of finishing additives.