Ecoinvest Ltd. processes around 40,000 tons of plastic waste every year at its headquarters in Pazardzhik, Bulgaria, turning it into high-quality regranulates and flakes. Founded in 2003, this family-owned company employs around 250 people and ranks among the leading recycling firms in Southeast Europe. For processing polyethylene (PE) films, Ecoinvest relies on an INTAREMA® TVEplus® system that efficiently handles even heavily contaminated LDPE and LLDPE film waste.

Customer orientation is a top priority at Ecoinvest. The Bulgarian company supplies clients across Southeast Europe and other European countries, as well as occasionally the Middle East and Asia with premium regranulates and colored flakes made from LDPE/LLDPE, HDPE, and PP. Each solution is tailored to meet specific customer needs and end-use applications.

Maximum flexibility thanks to TVEplus® technology

The current economic situation demands a high degree of flexibility from recycling companies, explains Orlin Tasev, CEO of Ecoinvest: "With film waste in particular, we source materials with very different qualities and purity levels. These range from edge strips from production facilities and very clean post-industrial films to heavily contaminated post-consumer waste from municipal waste collection systems." In addition, Ecoinvest relies on post-industrial LLDPE from the agricultural industry, which is either used as an additive to enhance material properties or for standalone products made from 100 per cent LLDPE.

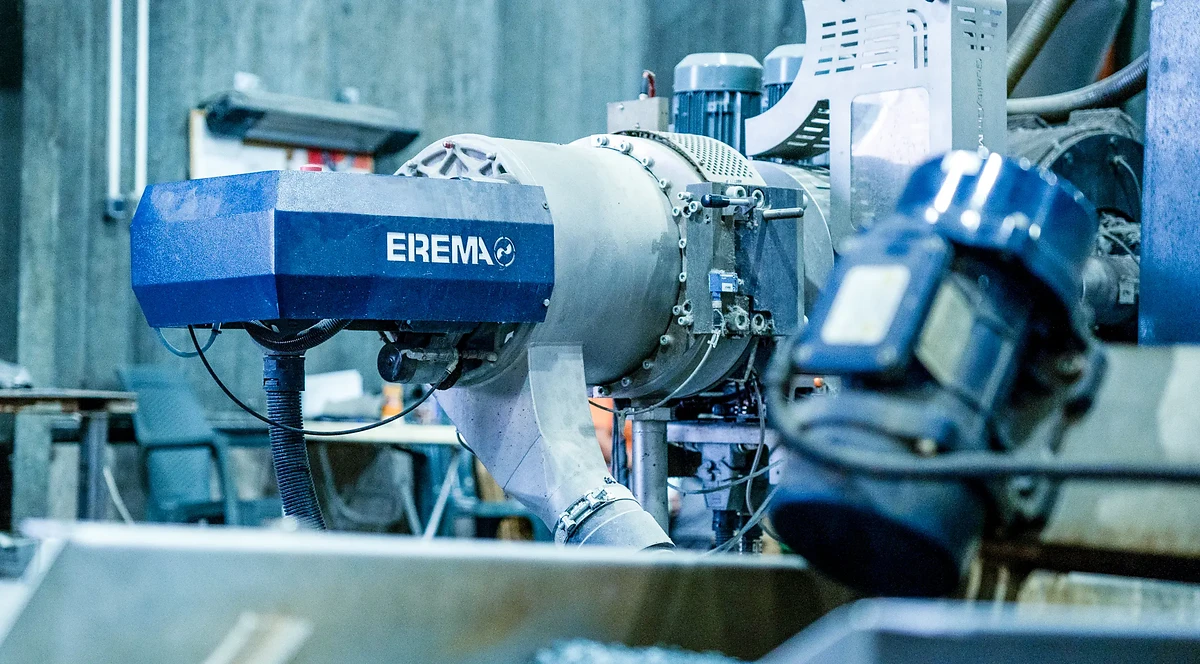

To meet these demanding conditions, Ecoinvest relies on proven brands when selecting its production systems. "EREMA is widely recognized as one of the leading companies in the industry and has demonstrated the quality and reliability of its products for many years. The INTAREMA® TVEplus® recycling system covers a very broad material spectrum with exceptional efficiency and quickly proved to be the ideal solution to meet our requirements and achieve the desired quality level," says Tasev.

Since mid-2023, the new INTAREMA® 1714 TVEplus® has been in operation, processing more than 12,000 tons of LDPE/LLDPE annually. "Combined with our 20 years of experience and modern optical sorting technology, the EREMA system enables us to process even challenging materials without compromising on quality or throughput," emphasizes Tasev. The special functionality of the INTAREMA® TVEplus® makes it possible to turn even difficult input – such as heavily printed films or very moist materials – into premium-quality regranulates.

“EREMA is widely recognized as one of the leading companies in the industry and has demonstrated the quality and reliability of its products for many years. The INTAREMA® TVEplus® recycling system covers a very broad material spectrum with exceptional efficiency and quickly proved to be the ideal solution to meet our requirements and achieve the desired quality level.”

Orlin Tasev, CEO of Ecoinvest

Premium regranulates for diverse applications

The interaction between the Preconditioning Unit (PCU) and TVEplus® technology makes this system unique. Thanks to the proven Counter Current® technology, a wide range of materials can be processed across an extended temperature range, while gentle melt preparation ensures that contaminants are effectively removed by the EREMA Laserfilter. For Ecoinvest, this is a clear quality advantage: "The process stability of the EREMA extruder is crucial for us. With INTAREMA® TVEplus®, we can consistently produce A-grade regranulates at high throughput rates – regardless of input material," says Tasev.

The regranulates are available in natural, amber, colored, and black, offering the variety needed for a wide range of applications. These range from industrial and agricultural packaging to construction films, waterproof membranes, and a wide range of consumer products like shopping or garbage bags. "Our LDPE regranulates feature a constant melt flow index (MFI), which is essential for stable extrusion processes and the production of high-quality packaging films," Tasev adds.

Ecoinvest sees its future firmly rooted in a sustainable plastics industry. In addition to further optimizing existing processes, the company is committed to increasing recycling rates and actively promoting the circularity of plastics in the region.